|

|

|

| ............................................................. |

|

|

| ........................................................ |

| From

the Editor |

|

Editorial

A. Abyad (Chief Editor) |

|

|

|

|

........................................................ |

Original

Contribution / Clinical Investigation

|

|

<-- Jordan, USA -->

Herpetic

Eye Disease and Glaucoma Related Diagnosis

[pdf version]

C. Dan Earley, Amal M Althawabi,

Paul R Cotran, Sarkis H Soukiasian

<-- Turkey, Lebanon, Australia -->

Cholelithiasis

may also be a consequence of metabolic syndrome

[pdf

version]

Mehmet Rami Helvaci, Mursel Davarci,

Orhan Veli Ozkan, Ersan Semerci, Abdulrazak

Abyad, Lesley Pocock

<-- Iran -->

SUMO1 pseudogene

3 (SUMO1P3) expression in human gastric cancer

and its clinical significance

[pdf version]

Hamid Reza Baradaran-Ghahfarokhi, Habib Malekpour,

Ehsan Nazemalhosseini Mojarad,

Hamid Asadzadeh Aghdaei, Majid Asadi-Samani,

Azar Baradaran

<-- Iran -->

Decoy Cell

Viruria in Kidney Transplant Patients. Does

it correlate with Renal Function?

[pdf version]

Akram Abedi, Mojgan Mortazavi,

Omid Mirmosayyeb, Shahram Taheri,

Nooshin Afsharmoghadam,

Majid Asadi-Samani, Shahram Sajadieh,

Azar Baradaran

<-- Iran, Austria -->

To determine

how frequently pregnant asthmatics are sensitive

to food and inhalation allergens

[pdf version]

Nasrin Fazel, Michael Kundi,

Erika Jensen-Jarolim,

Isabella Maria Pali-Schöll,

Asghar Kazemzadeh, Mojtaba Fattahi Abdizadeh,

Habibollah Esmaily,

Roya Akbarzadeh, Raheleh Ahmadi

|

........................................................

Special Education Feature

........................................................

International Health

Affairs

|

Chief

Editor -

Abdulrazak

Abyad

MD, MPH, MBA, AGSF, AFCHSE

.........................................................

Editorial

Office -

Abyad Medical Center & Middle East Longevity

Institute

Azmi Street, Abdo Center,

PO BOX 618

Tripoli, Lebanon

Phone: (961) 6-443684

Fax: (961) 6-443685

Email:

aabyad@cyberia.net.lb

.........................................................

Publisher

-

Lesley

Pocock

medi+WORLD International

11 Colston Avenue,

Sherbrooke 3789

AUSTRALIA

Phone: +61 (3) 9005 9847

Fax: +61 (3) 9012 5857

Email:

lesleypocock@mediworld.com.au

.........................................................

Editorial

Enquiries -

abyad@cyberia.net.lb

.........................................................

Advertising

Enquiries -

lesleypocock@mediworld.com.au

.........................................................

While all

efforts have been made to ensure the accuracy

of the information in this journal, opinions

expressed are those of the authors and do not

necessarily reflect the views of The Publishers,

Editor or the Editorial Board. The publishers,

Editor and Editorial Board cannot be held responsible

for errors or any consequences arising from

the use of information contained in this journal;

or the views and opinions expressed. Publication

of any advertisements does not constitute any

endorsement by the Publishers and Editors of

the product advertised.

The contents

of this journal are copyright. Apart from any

fair dealing for purposes of private study,

research, criticism or review, as permitted

under the Australian Copyright Act, no part

of this program may be reproduced without the

permission of the publisher.

|

|

|

| July 2017 - Volume

15, Issue 5 |

|

|

Gum Sisymbrium irio

effect on the quality attributes of baguettes

Leila Azadi

Mohammad Hojjatoleslamy

Hooman Molavi

Department of Food

science and technology,

Islamic Azad University,

Shahre Kord Branch,

Shahre Kord,

Iran

Correspondence:

Leila Azadi, Mohammad Hojjatoleslamy

Department of Food science and technology,

Islamic Azad University,

Shahre Kord Branch,

Shahre Kord,

Iran

Email: mohojjat@iaushk.ac.ir

|

Abstract

In this study,

gum Sisymbrium irio at different levels

of Control, 1/0, 1/5 and 2/0 percent (w,

w) and wheat flour, in loaf bread and

its impact on the quality attributes including

technological features, colours and staling

throughout the day, and various storage

mechanisms were evaluated. The results

of the evaluation of technical features,

showed that gum Sisymbrium irio increased

humidity, reduced stiffness and reduced

volume compared with the control bread.

By increasing the hold time, stale bread

and buns control treated with different

levels of gum Sisymbrium irio significantly

increased, shelf life.

Key words: Gum Sisymbrium irio,

loaf bread staling, colorimetric

|

In multi-phase systems such as bread dough, stable,

hydroxypropyl methyl cellulose emulsion is maintained

during baking. The hydrocolloid films, the phase

boundary between gas bubbles, are created and

provide stability of cells in the gas expansion

and other changes in the process. When the temperature

rises during baking, hydroxyl propyl methyl cellulose,

hydrocolloid gels formed through the interaction

of the chain and create a temporary network. This

will boost the dough during the expansion and

reduction in volume is prevented. The gel also

acts as a barrier against loss of moisture and

flavor without any adverse effect on soft tissue

of bread ( Appelqvist et al. 1997, Armero et al

.1997 ). The type and amount of hydrocolloids

in bread depends on the type of bread and also

properties of the flour used. Usually hydrocolloids

are used in loaf bread for tissue recovery, and

to strengthen the gluten network, creating a smooth,

uniform consistency and to delay staling. Carboxy

methyl cellulose (CMC) with an average size is

more consistent with the gum flour and has been

added to the dough in along with other components

such as sugar, so more water is absorbed. Some

types of carboxy methyl cellulose have very good

water holding capacity but relatively poor solubility,

Water holding capacity in bakery products is very

important. Carboxymethyl cellulose in food, increase

efficiency, to delay staling and also increase

product acceptance by consumers and increase shelf

life, Carboxy methyl cellulose is compatible with

other ingredients and bread improvers ( Bell,

DA. 1990 ). Effect of a combination of carboxymethyl

cellulose and hydroxyl propyl cellulose with other

additives such as enzymes and emulsifiers to check

and confirm that the addition of carboxymethyl

cellulose and hydroxyl propyl cellulose improves

the rheological properties of dough and bread

shelf life ( Sarkar et al.. 1995). Xanthan gum

and Locust, studies about the impact on the quality

of bread and colleagues show that this hydrocolloids,

stale bread delay and increased moisture in the

bread crumb has a positive impact on the stability

of the dough and the final product. Meat product

is used to increase the storage period ( Collar.1996

). In relation to the effect of adding gum on

the rheological properties and breadmaking quality

of the research was done and it was found that

gum production to the dough, improves dough stability

during fermentation and specific volume, water

activity increased bread moisture is better preserved

(Brady et al .1985, Selomulyo et al. 2007). In

the study several hydrocolloids with different

chemical structures in loaf bread were observed

and that some of these hydrocolloids are able

to a degree prevent loss of moisture during storage

and speed dehydration of bread crumb reducing

and preventing staling of bread. According to

various researchers, hydrocolloids to conserve

water and to prevent redistribution of bread,

as well as preserving more [brain] volume and

softness gas improves speed and reduces fresh

bread staling. Hydrocolloids in bakery products

can be used as fat replacers. Hydrocolloids, xanthan

and tragacanth effect on the levels of 0/5 and

1/5 on the rheological and sensory properties

of frozen dough from flour as a way to improve

the quality of structural damage caused by freezing

and frozen dough bread waste reduction and tails,

were studied. Effect of guar gum, pectin, alginate,

and xanthan Kapakaragynan looked on wheat flour

paste features and was also studied. They use

Mylugraf which showed that the addition of the

hydrocolloids in quantities of 5/0% and 1% (w

w) improves the properties of dough produced (Kim

et al . 1977). The use of frozen dough bread is

one way of effectively reducing the rate of bread

staling. In this study, the effect of hydrocolloids,

xanthan and tragacanth at two levels: 5/0 and

5/1 percent (w weight based on flour) on the rheological

properties of dough and hamburger buns made from

frozen dough stored (at oC18- for 2 weeks) and

sensory quality were studied. The results of the

study of several hydrocolloid with chemical structures

from different loaf bread showed that some of

these hydrocolloids are capable of loss of moisture

during storage of bread and speed dehydration

bread crumb, reduce the staling prevent (Guarda

et al , 2004 , MacRitchie et al- . 1973). The

results of Rojas and colleagues showed that the

forming properties of wheat starch paste greatly

improved by adding hydrocolloids. In addition,

in several studies of gum as a fat replacer, is

used to replace gluten and source of dietary fiber

(Appelqvist et al. 1997). Effect of hydrocolloids

alginate, xanthan and hydroxy propyl methyl cellulose

the rheological properties of dough and bread

quality, were examined. The results showed that

the addition of these substances increases during

fermentation dough stability and increased specific

volume and holding., Also, adding the hydrocolloids

reduces the hardness of the bread crumbing (Selomulyo

et al . 2007). They found that all hydrocolloids

are able to hold moisture loss during crumbing

of bread and reduce the rate of water loss and

moisture to increase the bread crumb ( Guarda

et al , 2004).

In this study, Sisymbrium irio Golestan Mohammadi

was purchased from flour factories. The use

of dry yeast factory production FARIMAN Mashhad.

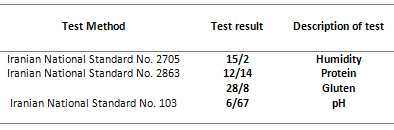

In Tables 1 and 2, respectively Sisymbrium irio

characteristics of flour and gum used is listed.

Gum prepared Sisymbrium irio

Sisymbrium irio was 40 ° C for 4 hours in

the water, after passing through the filter,

the material after drying (gum) was added to

breads and cakes.

Baking bread

Bread baguette in the bread industry unit according

to Lee, who, has been mentioned in Table 3,

were produced. After sieve weighing the dry

ingredients for making bread they can be mixed

together. The yeast suspension in water with

a temperature of 35 ° C containing 5.0%

sucrose for 10 minutes to activate the yeast

cells was prepared, and was added to the above

materials. Finally, the remaining water was

also added to the formulation. All compounds

were mixed at 1 mixer for 10 minutes. Pulp obtained

from the following 4 treatment groups were prepared

so that all of their components except Sisymbrium

irio gum, were considered constant.

Treatment 1: No gum Sisymbrium irio

Treatment 2: containing 1.0% gum Sisymbrium

irio

Treatment 3: 15/0 percent gum containing

Sisymbrium irio

Treatment 4: 2.0% gum containing Sisymbrium

irio

90 gram pulp were split into pieces and shaped

in the form, respectively. Templates in the

fermentation chamber temperature and relative

humidity of 85% C ° 38 were placed for 60

minutes. Action Bake for 25 to 30 minutes at

a temperature C ° 240 industries in the

oven with steam injection was performed. After

baking, breads were extracted from the mold,

and cooled at room temperature for half an hour

and then were packed in polypropylene bags until

tests were kept at the right temperature.

Table 1: Wheat and Flour Quality Characteristics

in terms of dry matter

Statistical analysis

Statistical tests based on completely randomized

design with three treatments and three replications.

First, by analyzing the variance in the comparison

test Duncan means of a significance level of

5% was conducted to evaluate the significance

of the results. Statistical analysis using Excel

software and SPSS version 21 was conducted.

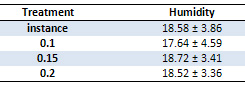

Table

2,

shows

that

the

control

samples

had

the

sample

had

the

highest

humidity

and

low

moisture

content

in

the

sample

was

found

to

contain

1.0

per

cent

Gum

Sisymbrium

irio.

Eskandari

and

his

colleagues,

as

well

as

Yarmand

and

Ardebil's

similar

results

were

reported

(Yarmand

et

al

.

2005,

Pouresmaeil.

2010).

Russell

et

al.,

Guarda

and

colleagues

and

Pooresmaeel

also

had

similar

results

from

adding

hydrocolloids,

xanthan

gum,

sodium

alginate,

Kapakaragynan,

hydroxypropyl

methyl

cellulose

and

guar

and

increase

their

concentration

acquired

(Bouaziz

et

al

.

2010,

Guarda

et

al

.

2004).

Table

2:

Increase

in

moisture

content

compared

to

control

samples

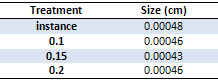

Volume

Gum

Sisymbrium

irio

at

1/0,

15/0

2/0%

on

bread,

reduced

size

compared

with

the

control

bread.

Sisymbrium

irio

gum

may

reduce

the

production

of

cavities

in

bread.

This

reduction

could

be

due

to

reduced

capacity

as

a

result

of

reducing

the

amount

of

gas

in

the

dough

gluten.

The

results

obtained

in

the

investigation

(

-Bazayz

and

colleagues

in

2010),(Garmyla

and

colleagues

in

2011),

as

well

as

liquids

.

Table

3:

Gum

Sisymbrium

irio

at

1/0,

15/0

2/0%

on

bread,

reduced

size

compared

with

the

control

bread

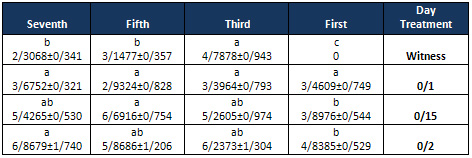

Firmness

Hardness,

resistance

to

deformation

crumb

texture

is

a

characteristic

that

in

most

cases

is

used

to

assess

staling

(212)

.

On

the

seventh

day

the

most

difficult

to

control

bread

and

the

least

amount

of

hard

bread

with

2.0

percent

in

the

first

batch

was

awarded

Sisymbrium

irio

gum.

Retrogradation

is

a

function

of

the

difficulty

and

thus

increases

with

increasing

difficulty

retrograde.

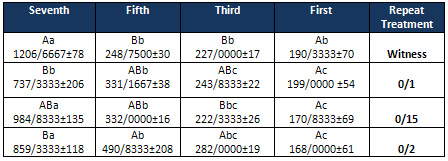

Table

4:

Compare

the

average

impact

factor

gum

Sisymbrium

irio

difficult

and

time

consuming

bread

Continuity

Back

to

the

flexibility

of

the

tissue

and

its

continuity

depends

on

the

initial

state.

Gum

Sisymbrium

irio

may

cause

damage

to

the

gluten

network

structure

and

causes

reversal

to

the

original

state.

Therefore,

the

addition

of

gum

Sisymbrium

irio

reduced

coherence

factor

in

bread

samples

containing

gum

Sisymbrium

irio,

against

controls.

Therefore,

by

increasing

the

gum

and

over

time,

decreases

the

staling.

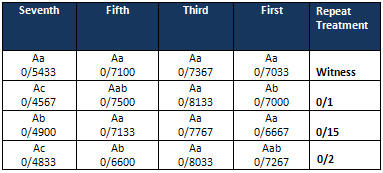

Table

5:

Compare

the

average

impact

factor

gum

Sisymbrium

irio

and

time-consuming

integration

of

cake

A,

B

and

C

show

a

significant

difference

between

the

rates

on

different

days

and

a,

b

and

c

indicate

the

presence

of

significant

differences

in

different

treatments

(0/05>

p).

The

resinous

gum

Appendix

3

can

be

downloaded

by

examining

the

sample

containing

the

resinous

gum

Sisymbrium

irio

at

intervals

less

than

the

control

sample

immediately

after

cooking.

Resinous

and

other

parameters

of

texture

analysis.

This

parameter

assists

to

digest

food

and

prepare

it

for

swallowing.

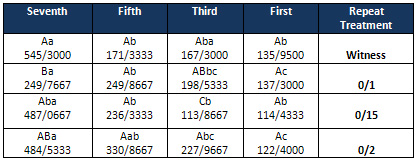

Table

6:

Compare

the

average

impact

factor

of

gum

Sisymbrium

irio

and

time

Smghyt

bread

A,

B

and

C

show

a

significant

difference

between

the

rates

on

different

days

and

a,

b

and

c

indicate

the

presence

of

significant

differences

in

different

treatments

(05/0>

p).

Image

Processing

Compared

with

the

control

of

bread

crumb

with

gum

and

increased

levels

of

color

which

was

darker.

Since

the

Maillard

reaction

is

not

involved

in

making

the

bread

crumb

color,

dark

bread

crumb

is

likely

caused

by

gum

Sisymbrium

irio,

according

to

the

results

obtained

by

Pooresmaeel

due

to

compression

of

the

grain

tissue

due

to

decreased

volume,

and

gum

gel

formation

Sisymbrium

irio

is

(Bouaziz

et

al

,

2010).

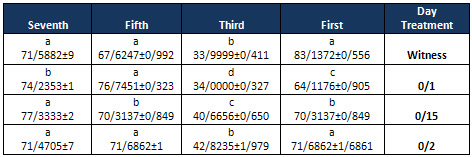

Table

7:

Compare

the

average

impact

factor

of

gum

Sisymbrium

irio

and

time-consuming

brown

bread

a,

b

and

c

indicate

the

presence

of

significant

differences

in

different

treatments

(05/0>

p).

Results

Table

(8)

,

shows

that

in

the

control

sample

had

reduced

color

change

over

time,

while

gum

samples

containing

2.0

Sisymbrium

irio

15/0

and

color

changes

were

observed

with

the

passage

of

time.

Table

8:

Compare

the

average

impact

factor

of

gum

Sisymbrium

irio

and

time-consuming

color

variations

in

bread

a,

b

and

c

indicate

the

presence

of

significant

differences

in

different

treatments

(05/0>

p).

Evaluation

of

Porosity

Results

Tables

(7)

to

(8)

obtained

from

analysis

of

texture

images

show

that

by

increasing

the

pore

size

it

reduced

Sisymbrium

irio

gum

that

can

be

difficult

due

to

reduced

volume

and

increased

bread.

The

mean

pore

diameter

of

the

holes

indicate

the

area

is

reduced,

decreasing

in

height

and

diameter

of

these

changes.

These

results

are

consistent

with

the

results

of

research

of

S.Han

and

colleagues

(Ozkoc

et

al

.

2009).

In

addition,

during

the

leavening,

the

bubbles

that

are

produced

during

the

mixing

within

the

dough

expand

their

gas

production

by

yeast.

Thus,

the

stability

of

bubbles

is

most

important

in

that

the

main

cause

of

instability

is

connected

to

individual

gas

cells.

Thick

layer

of

bubbles

on

the

inter

connectedness

of

the

dough

is

reduced

(Volpini-Rapina

et

al

.

2012).

Sensory

evaluation

Bread

properties,

such

as

colour,

aroma,

taste,

are

enhanced

by

increasing

the

gum

Sisymbrium

irio

points

respectively.

Related

to

the

appearance

of

bread

it

is

similar

to

the

results

obtained

in

their

research

confirms

that

Shalin

and

colleagues

(Mettler

et

al

.

1993,

Sidhu

et

al

.

1988).

With

the

increase

in

chewing

ability

bread

with

Sisymbrium

irio,

shows

improvement

and

that

corresponds

with

the

results

of

Guarda

and

colleagues

(Guarda

et

al

.

2004).

According

to

the

results

of

tests

to

assess

the

properties

of

bread,

it

was

found

that

bread

with

1/0

Drsdsmgh

Sisymbrium

irio

gives

the

best

sensory

quality.

Gum

Sisymbrium

irio

in

increased

levels

in

bread

increased

hardness,

cohesiveness,

its

resinous,

elasticity,and

chewiness

.

along

with

cutting

ability,

brightness,

and

reduced

porosity.

Sensory

evaluation

factors

decrease

with

increasing

gum.

Reduced

volume

and

crumb

and

crust

color

darkening,are

the

unfavorable

characteristics

of

the

gum.

It

should

be

noted

that

treatment

with

1.0

per

cent

Gum

Sisymbrium

irio

enhances

the

sensory

properties

of

bread

better

than

the

control

sample.

Acknowledgment

With

special

thanks

to

the

Research

and

Technology

deputy

of

the

Islamic

Azad

University,

sharkord

branch.

1-

Appelqvist

IAM,

Debet

MRM.

Starch-biopolymer

interactions:

a

review.

Food

Rev

Int

1997;

13:

163-24.

2-

Armero

E,

Collar

C.

Texture

properties

of

formulated

wheatdoughs.

Z

Lebensm-

Unters

Forsch

1997;

204:136-45.

3-

Bell

DA.

Methylcellulose

as

a

structure

enhancer

in

bread

baking.

Cereal

Foods

World

1990;

35:

1001-1006.

4-

Bouaziz,

M.

A.,

Amara

,

W.

B.,

Attia,

H.,

Blecker,

C.,

&

Besbes,

S.

(2010).

Effect

of

the_addition

of

de-fatted

date

seeds

on

wheat

dough

performance

and

bread

quality,

Journal

of

Texture

Studies,

41,

511-531.

5-

Brady

PL

and

Mayer

SM,

1985.

Correlation

of

sensory

and

instrumental

measures

of

bread

texture.

Cereal

chemistry

62(1):

70.

6-

Collar,

C.E.1996.

Retrogradation

of

the

starch

fraction

in

wheat

bread.

Food

Science

and

Technol.Int.

2:

323-333.

7-

Guarda

A,

Rosell

CM,

Benedito

C,

Galotto

MJ

(2004)

Food

Hydrocolloid.

18:

241-247.

8-

Kim,

S.K.

and

D'Appolonia,

B.L.

(1977a)

Bread

staling

studies.

I.

Effect

ofprotein

content

on

staling

rate

and

bread

crumb

content

on

staling

rate

and

bread

crumb

pasting

properties.

Cereal

Chemistry,

54,

207-15.

9-

Mettler,

E.

and

Seibel,

W.1993.Effect

of

emulsifiers

and

hydrocollid

on

whole

wheat

bread

quality.

Cereal

chemistry.70:

373-377.

10-

MacRitchie

F,

Gras

PW.

1973.

The

role

of

flour

lipids

in

baking.

Cereal

Chem

50:

292.

11-

Ozkoc,

S.

O.,

Sumnu,

G.,

and

Sahin,

s.

2009.

The

effects

of

gums

on

macro

and

micro-structure

of

breads

baked

in

different

ovens.

Food

hydrocolloids,

23:

2182-2189.

12-

Pouresmaeil,

N.2010.

Formulation

and

production

of

prebiotic

gluten

free

bread

using

transglutaminase

enzyme

and

hydrocolloids:

guar

and

xanthan.

M.Sc

Thesis,

Department

of

Food

Science

and

Technology,

School

of

Agriculture,

Tarbiat

Modarres

University,

Tehran,

Iran

13-

Rojas

J.A.,

Rosell

C.M.,

Benedito

de

Barber

C.

1999.

Pasting

properties

of

different

wheat

flour-hydrocolloids

system.

Rojas

1999.

Food

Hydrocolloids

13,

27-33.

14-

Sarkar

N,

Walker

LC.

Hydration-dehydration

properties

of

methylcellulose

and

hydroxyprophylmethylcellulose.

Carbohyd

Polym

1995;

27:

177-85.

15-

Selomulyo

VO,

Zhou

W.

Frozen

bread

dough:

effect

of

freezing

storage

and

dough

improvers.

J

Cer

Sci

2007;

45(1):

1-17.

16-

Sidhu,

S.

J.

and

Seibel,

W.1988.

Measurment

of

chapati

texture

using

Zwick

universal

testing

machine.

Lebensm

Wiss.

U.

Technal.

21:147-150.

17-

Volpini-Rapina

LF,

Sokei

FR,

Conti-silva

AC.

2012

.

Sensory

profile

and

preference

mapping

of

orange

cake

with

addition

of

prebiotics

Inulin

and

oligofructose.

LWTFood

Science

and

Technology1-6.

18-

Yarmand,

M.

S.,

&

Seyedein

Ardebili,

M.

(2005).

Effect

of

Gluten

and

Malt

Flour

on

Staling

and

Quality

of

Barbari

Flat

Bread.

Iranian,

J.

Agric.

Sci,

36,

591-602.

|

|

.................................................................................................................

|

| |

|